One of the less desirable features of vintage cars is they were built before automotive safety grabbed the steering wheel and took control of the industry.

Most of the safety improvements were designed to prevent harm to the vehicle’s occupants and, likely more importantly, the car company’s bottom line after the dawn of ambulance chasers.

There are many automotive safety features that we take for granted in 2021, but today’s drivers undoubtedly become acutely aware of the lack of safety items whenever they get behind the wheel of a retro ride.

Jim Sutherland

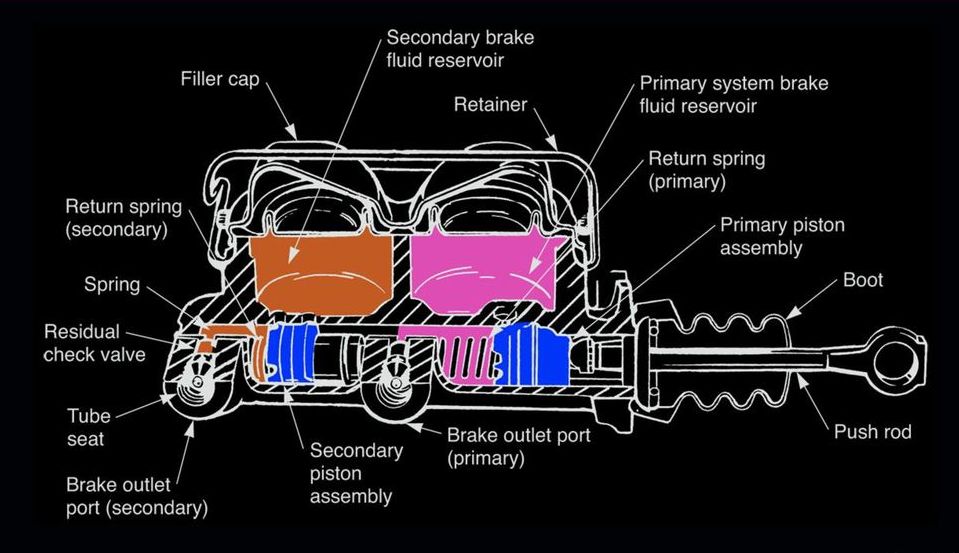

One of the lesser-known throwback non-safety features is the single reservoir master brake cylinder. A single reservoir master cylinder was a common mechanical component on most domestic vehicles until the late 1960s when auto manufacturers were forced by legislation to add dual reservoir master cylinders to their cars.

It was a significant moment that went largely unnoticed by consumers because master cylinders are located under the hood-or hidden even more deeply from sight. Unnoticed right up to the moment when a leak in the single master cylinder braking system turned the unlucky driver into a very unwilling stuntman with no brakes.

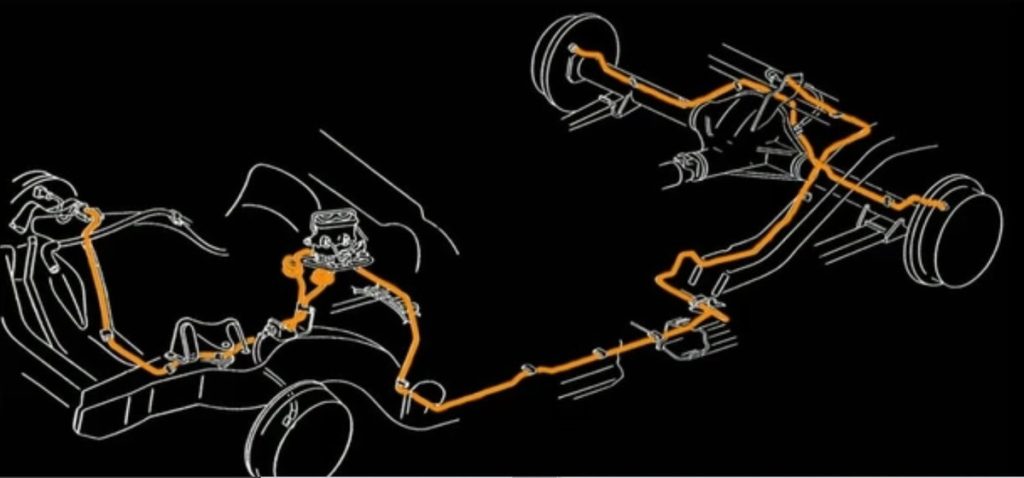

A single master cylinder brake system offered no safety net from total brake failure, unlike a dual master cylinder that separates the front and rear brake lines into two chambers under the hood. As a result, a driver would be able to slow down a dual master cylinder car-equipped in a situation with either front or rear brake line failure since the other half of the brake system would still work for them.

I was well-armed with the above information when I tackled a master cylinder retro fit on an older vehicle. For me, there were too many positives regarding a swap from a single master cylinder to a double master cylinder on a vintage car, including the grim fact that my best stunt driving days occurred roughly between the ages of 16 and 21 during the 10-feet-tall-and-bullet-proof phase of my life. Truth be told, I was not particularly interested in reliving any of my young and extremely brash driving moments in life.

The two other major reasons? Most master brake cylinder swaps are relatively easy and can be switched back to the original equipment if that is the future direction taken by an owner.

“Relatively easy” is a term to which mechanically inclined people can relate, but it is not a term that can be attached to mechanical morons like me. If there is an easy path to a mechanical goal, I will find the most difficult, painful, and soul-crushing path to the same destination.

A switch to a dual master cylinder had me seriously considering Flintstone foot brakes after Day I, but I soldiered on to my intended goal, despite a series of mechanical misadventures in very tight places. For example, I was never meant to squeeze under the steering wheel of a retro domestic car (or any car for that matter) since I was about 11–plus I have no yoga training to make me bendier. But a new master brake cylinder forced me into a tight space under the steering wheel to separate the old master cylinder from the firewall. It was a little like stuffing an adult salmon into a goldfish bowl.

Manual dexterity is the ability to use one’s fingers for detailed and intricate work, but this talent is merely a concept for left-flippered seals like me. I should mention that I also had to change out a wheel cylinder after breaking the bleeder valve on the old one, therefore manual dexterity was in the cards for me–whether I wanted to play or not.

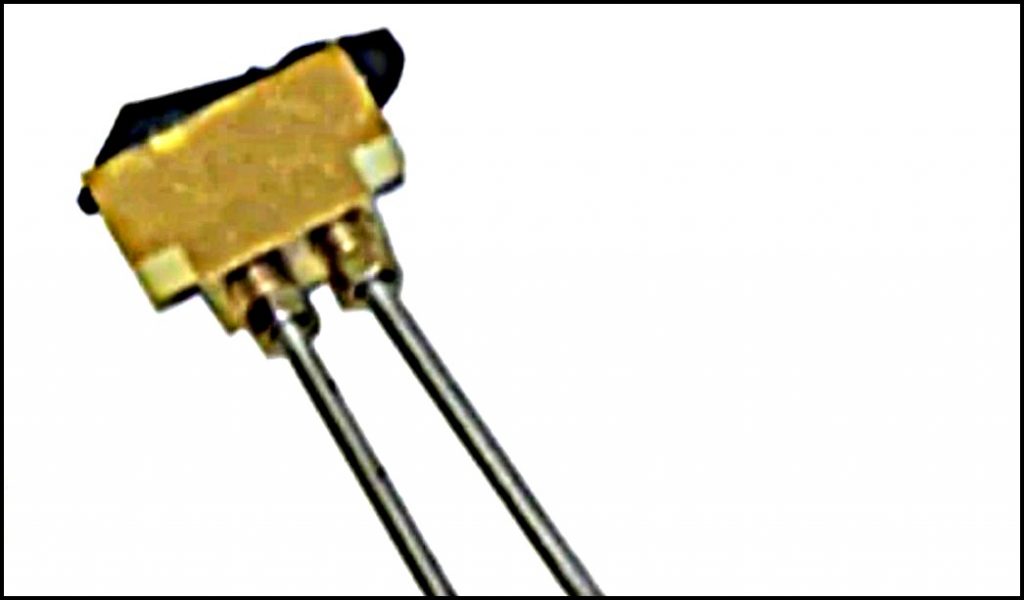

There were several instances when I was forced to use my right hand to attempt a difficult threading process with brake lines into the junction box because my dominant left hand was unable to meander into the right position. The saving grace was the fact we live in a right-handed world, so lefties like me are forced to use our other hand much more than most of the righties use their left hand. Plus I have limited finesse with either hand.

Other dexterity issues included inaccessible bolts on the wheel cylinder that forced me to improvise with their removal and replacement. Most of my efforts involved a painfully slow process with two small bolts that required microscopic finger turns into an extremely small and hidden target area.

I hated to end this kind of fun, so I was fortunate and had to repeat the entire process. I neglected to connect the brake line hose and it could be tightened down only if the wheel cylinder was not secured in place so it could be threaded onto the brake line hose.

My good fortune continued when I was also granted an opportunity to toughen up my hands every time a tool slipped and made me accidentally punch a metal component of the car. The list included the old car’s wheel well, frame and steering column, although the last one made me forget about the cramped area directly under the steering column for a few minutes.

The three-day brake job adventure flew by like three years for me, but eventually I won the battle and replaced the single chamber master cylinder. I completed the task by bleeding the brakes after a careful search for any extra parts turned up negative. Then it was time for my traditional singing and dancing celebration.

My final view? Much respect for the mechanically gifted among us–and no small degree of envy.

Jim Sutherland

BY: Jim Sutherland

Jim Sutherland is a veteran automotive writer whose work has been published by many major print and online publications. The list includes Calgary Herald, The Truth About Cars, Red Deer Advocate, RPM Magazine, Edmonton Journal, Montreal Gazette, Windsor Star, Vancouver Province, and Post Media Wheels Section.

- CLICK HERE to Sign Up for the Newsletter

- CLICK HERE to Like us on Facebook

- CLICK HERE to Follow us on Twitter

- CLICK HERE to Follow us on Pinterest